Masking

for surface finishing

Passgenaues Abdecken für perfekte Ergebnisse

Not every surface of a component should or may be coated. Especially in electroplating, anodising or painting. With precise masking, we specifically protect fitting surfaces, drill holes, contact points or functional areas and thus ensure technically flawless results and maximum dimensional accuracy.

Masking is a crucial step in the surface finishing process. Defined areas of a workpiece are masked before coating in order to specifically exclude them from electrochemical processes.

This selective processing is particularly necessary when:

must be complied with

should remain free

should remain unprocessed

between coated and untreated surfaces is desired

Masking protects certain areas of a component from subsequent surface treatment. This is particularly important if different material properties or functionalities are to be retained on a workpiece.

Through professional masking, we ensure that your components are finished exactly to the desired specifications.

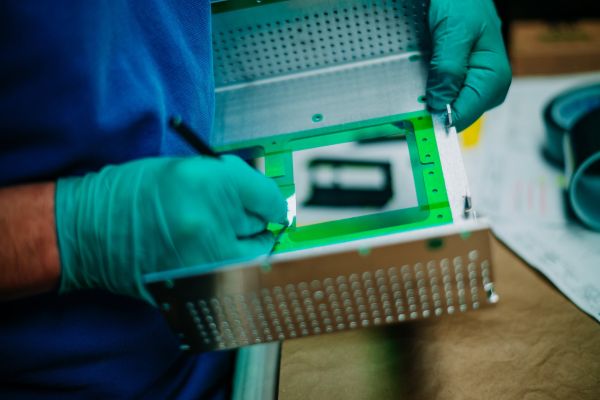

We rely on customised masking solutions depending on requirements. From manual masking to customised plugs and masking films to specially manufactured masking devices.

Masking involves covering certain areas of a component before coating. As a result, these areas remain uncoated and functional – for example, fits, sealing surfaces, threads or electrical contact points.

Masking is used, for example, for electroplating, anodising, powder coating and painting – wherever only selected surfaces are to be coated.

Depending on the component and requirement, we use:

Because the coating can otherwise affect undesirable areas – for example through layer build-up on mating surfaces, electrical insulation at contact points or visually unclean transitions.

Imprecise masking can lead to dimensional deviations, loss of function or reworking. That’s why we rely on experienced employees and harmonised processes to precisely adhere to coating limits.

Yes. Precise masking is also possible for multi-dimensional geometries, drill holes or sensitive zones – by combining different techniques and, if necessary, customised masking aids.